FEATURE

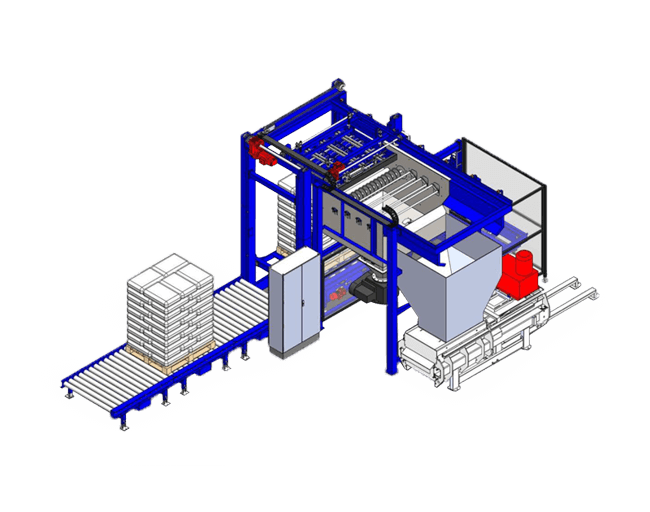

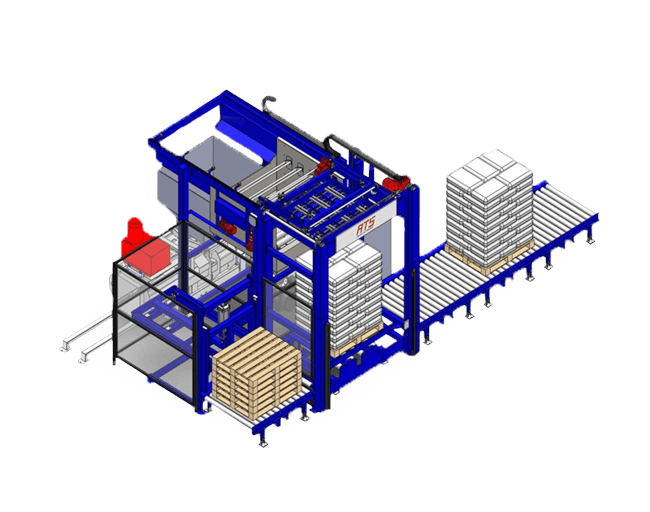

- Expandability: possibility to

- Add a bag compacter

- Add a pallet stacker

- Implement in complex control system with full process control - Flexibility (additional options, executions can be discussed)

- Robust execution

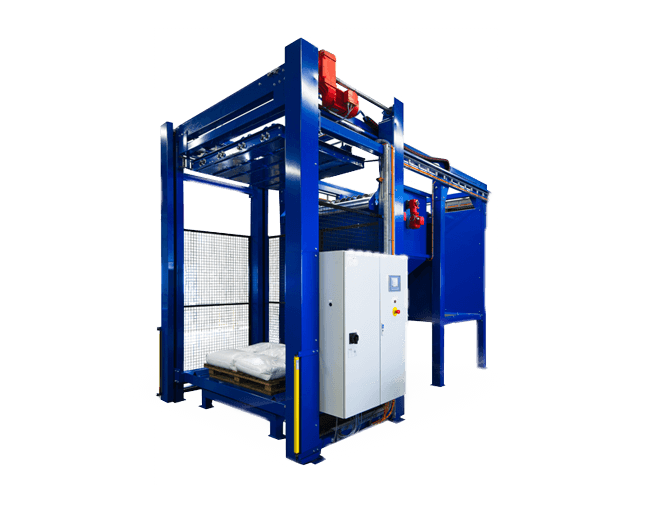

- Separated steady movements

- Electrical lift executes vertical movement

- Shuttle executes horizontal movements

DESCRIPTION

- With the fully automatic bag emptying machine, granulate bags of 25 kg can be opened and emptied into a receiving bin.

- The capacity of the machine is between 10 and 15 tons of granules per hour.

- Emptying is better than 99.98%!

- It is also possible to transport or drop the empty bags (in)to a bag compactor or baler.

- The granulate in the receiving bin is transported from the bin by means of a granulate pump into the pneumatic transport system.

- This system provides a durable and reliable transport to storage silos.

Alternative designs and extra options

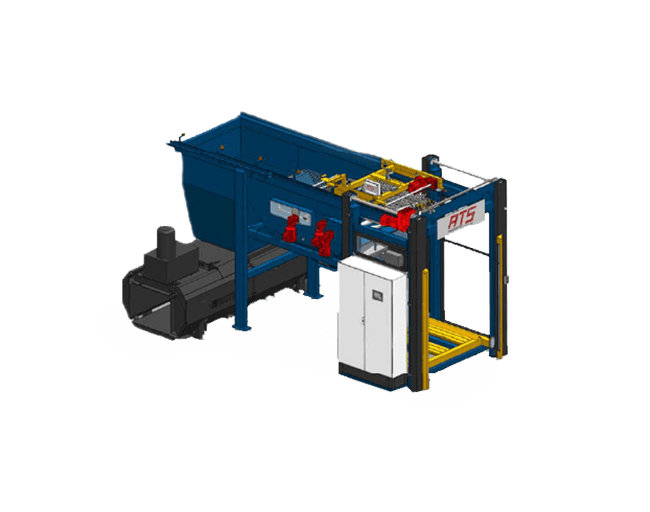

- XL unit: Suitable for dumping granulate into containers, big bags, octabins or truckloads;

- Automated cleaning: This machine can clean itself after a batch, so it is immediately ready for a different product

- Automatic pallet transport (in and out)

- Integrated palletstacker for stacking the empty pallets

- Integrated bag compactor or baler for the empty bags

Specification of Bag Emptying Machine

- Feeding opening L x W: 1030x950 mm

- Channel W x H: 950 x 700 mm

- Dimensions L x W x H: 3550 x 1410 x 1940 mm; without hopper

- Max. feeding volume: 0,68 m³

- Volume throughout in idle speed: 72 m³/h without binding time

- Pressing force: 300 KN; specific pressing force: 45 N/cm²

- Cycle time: 34 s

- Drive power uptake: 11 KW; fuse: 35 A; delay melting fuse

- Power connection: 460 V, 60 Hz

- Channel outlet fully automatic control

- Binding system: manual, 4-fold; binding with polyester strap reels

- Low oil level switch with over temperature stop function

- Equipped with Operating hour meter and Bale length meter

- Starting system by light barrier

- Hydraulic central drive

- Central control system with function and failure display by Siemens PLC control

- Bale length pre-selection via text display

- Revision door (670x670mm) with Plexiglass

- Total Load: 11 KW