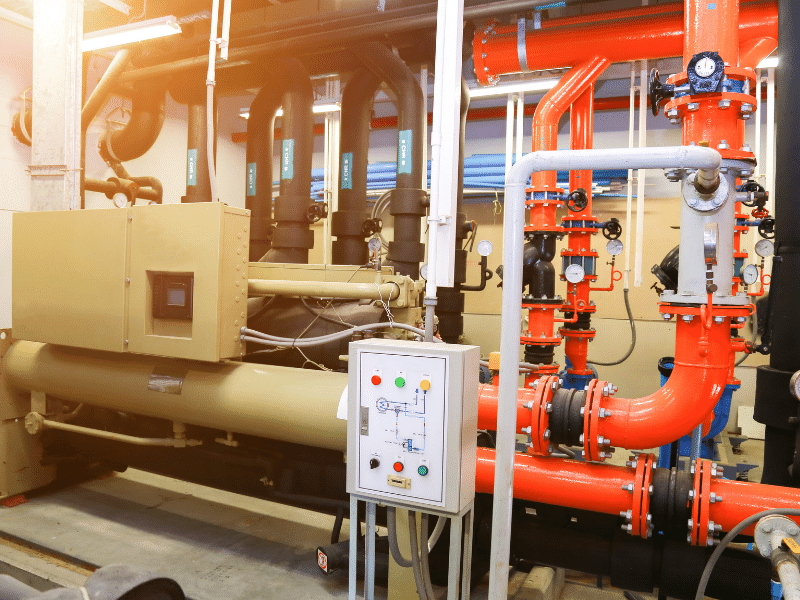

An industrial water chiller is necessary for any factory with large machinery that generates constant heat. It helps keep your facility at a low temperature and cool down your internal machine equipment. So, understanding how these chillers work will help you make the right decision for your cooling needs. In this article, we will focus on industrial water chillers.

What Is a Chiller?

Chillers are widely used in commercial and industrial facilities. A chiller is a refrigeration system used to cool down liquid processes or mechanical equipment. The chiller’s primary function is to remove unwanted heat while maintaining a stable temperature, pressure, and current in the machine or production process. This is achieved by circulating the heat-absorbing process with the refrigeration cycle inside a chiller.

Industrial chillers are used to control the cooling (direct or indirect) of products, mechanisms, and machinery in a variety of industries. Although there are different types of industrial chillers, all chillers use air or water as a cooling method during the refrigeration cycle.

For example, the air-cooled chiller cools the chiller system with fans, while a water-cooled chiller cools the chiller system with circulated water from the cooling tower. These chiller systems are able to cool the water to below ambient temperature or below zero. Water chiller capacities are commonly measured in cooling tons, KCAL/hr, or BTU/hr.

Why Do You Need A Chiller System?

Industrial operations emit heat through the use of friction and high-powered equipment, such as furnaces or engines, or temperature-sensitive materials like plastics. To increase the lifespan of heavy-duty equipment, as well as to speed up production via a shortened cycle time, chiller units are installed to circulate cooled liquid through equipment.

Selecting the right chiller for your application will help you save costs, reduce downtime, as well and elevate production capacity and operational efficiency. The two major industrial chillers applied in most facilities today are air-cooled and water-cooled chillers, which we will discuss further in the following section.

Types of Industrial Chillers: Air-Cooled & Water-Cooled Chillers

There are two types of condensers used in chillers: water-cooled and air-cooled. In a refrigerant cycle, the hot freon from the compressor has to be cooled in the condenser. And then, it enters the expression valve into the evaporator to generate chilled water in the chiller and achieve the desired cooling cycle.

Air-Cooled Chillers

An air-cooled chiller is equipped with a condenser that uses ambient air to cool the hot refrigerant gas. It is usually installed in an area with good airflow, as it relies on the use of fans, instead of cooling towers, to facilitate heat dissipation. An air-cooled chiller unit actively absorbs the heat from the processed water and then transfers this heat into the air.

Water-Cooled Chillers

A water-cooled chiller is equipped with a condenser that uses water from a cooling tower to cool the refrigerant gas. After the refrigerant is cooled and released via an extension valve, it will cool down the water that circulates in the chiller and reach the target temperature. In other words, the processed water works as a medium for heat transfers.

Air or Water Chillers: Which Better Suits Your Needs?

Both air-cooled chillers and water-cooled chillers are designed to facilitate the discharged heat from the production process. Both types of chiller produce the same cooling capacity under the same power as the compressor. Hence, it is the working environment and the purpose of use that should dictate your decision-making process.

Flying Tiger is a top manufacturer with over 40 years of experience in the water/air chiller business. Globally, it represents a prestigious name in the market. Our water chiller design can control the target temperature between +-0.5°C (able to be customized the tolerance to +-0.1°C). Also, we can modify the water tank (internal or external) to prevent temperature spikes. To understand how we build reliable and customizable chillers to fulfill cooling needs in various sectors, follow the link and explore our Chiller & Cooling Water Series.

How Do Industrial Water Chillers Work?

Nearly every industrial process generates heat. If this unwanted byproduct accumulates over time, inefficiency can drag down the productivity of your machinery and factory; excessive heat could even lead to shutdowns or early equipment failure. Therefore, it is necessary to incorporate the cooling process into your industrial process system design to avoid these issues.

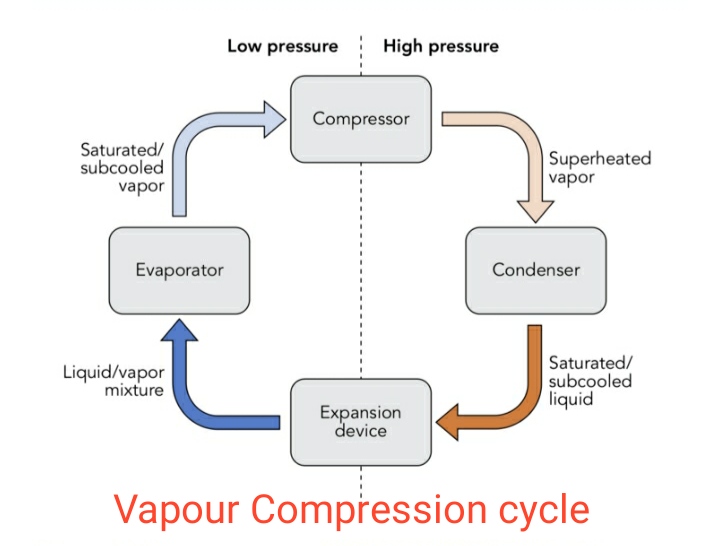

The essential components of a chiller are a compressor, condenser, expansion valve, and evaporator. They work in unison to circulate a refrigerant that removes heat from a process, operation, or space.

- Compressor: This is the major component of a refrigeration unit. Compressors in all chillers have the same function: to circulate the refrigerant (freon gas) and convert the gas from low-pressure to high-pressure before it travels to the condenser, where it discharges its heat.

- Condenser: It cools the gas by transferring the heat from the refrigerant to the outdoor cooling medium (air or water). It also works to condense the refrigerant, converting it from a gas to a liquid.

- Expansion valve: This is where the liquid refrigerant passes through before it enters the evaporator for heat exchange. Its primary function is to lower the high pressure and temperature of the refrigerant liquid when passing through the expansion valve (also known as a throttle valve). Next, the valve converts the refrigerant into a low-pressure and low-temperature wet vapor. This is then sent into the evaporator for heat exchange.

- Evaporator: This is where the actual heat exchange happens. At this stage, the processed water from the expansion valve enters the evaporator to kick off the heat exchange and cooling process.

Which Industries Need a Water Chiller?

Water chillers are used in various industries. Some of them include the following:

-

Plastic manufacturing and processing

-

Metal forming

-

Food and beverage processing

-

Machinery

-

Chemical & pharmaceutical

-

Medical (MRI, CT scanner, x-ray, linear accelerator, laboratory)

-

Shoe industry

-

Laser cutting

-

Transportation manufacturing

-

Semiconductor

-

Composite manufacturing

Things to Consider Before Selecting a Water Chiller System

There are numerous benefits of using a water chiller in a factory. However, you can only achieve these if you have the right chiller installed. We suggest you evaluate the following questions before purchasing a water chiller system.

- What's the heat load of your intended application?

- What coolant type, target temperature, and flow rate does the chiller system provide?

- In what environment will the water chiller be installed, and what is the site condition?

- Does this water chiller model meet or exceed the required capacity? (check the chiller performance curves)

Save Time with Flying Tiger's Chiller & Cooling Water Series

Beyond professional consultation, an ideal manufacturer designs water chiller models that keep your components cool during processes and shorten production time. Here are a few benefits of choosing Flying Tiger's industrial chillers:

Accurate Temperature Control

Through our experience working with industrial processes, we understand the importance and necessity of accurate temperature control. Therefore, Flying Tiger chillers provide cost-efficiency design and recirculation tanks to maintain temperature accuracy of +- 0.5°C and even +- 0.1°C with customizable design.

Modularization

With our comprehensive designs and supportive flexibility, all our industrial chillers are adaptable to your future growth. By adopting the modularization design, we effectively distribute the risk of a complete system failure through multiple compressor systems in one unit.

Energy Saving (Inverter Chiller)

Flying Tiger manufactures water chillers that are both economical and energy-efficient. With each compressor equipped with an inverter function, our chiller models can save 15-50% of energy (varied with differences in frequency and regions).

Reduce Cycle Times with Our Water Chiller Solutions

Regardless of your industry and process, making sure that you have sufficient cooling is critical to productivity optimization and cost savings. To achieve this, first, you must cool your industrial applications properly.

Flying Tiger offers a versatile line of industrial water/air chillers for a wide range of applications. With an immediate reduction in water use and a consistent cooling water temperature, our chiller models offer a significant improvement to the process and a quick return on investment. Contact Us Today for more information or assistance with a quote!

Back