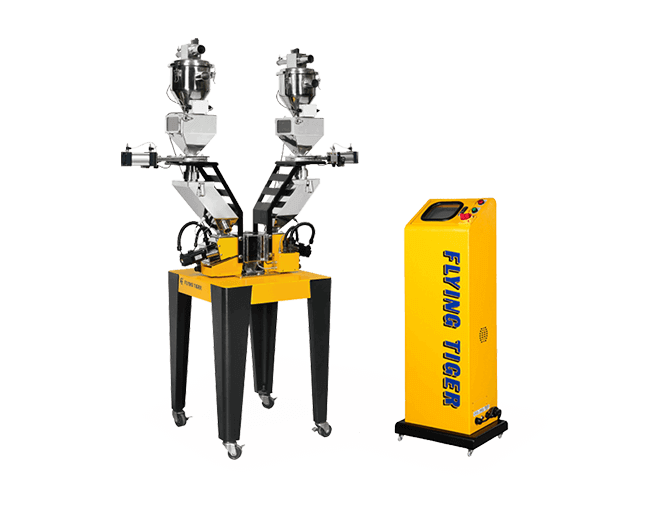

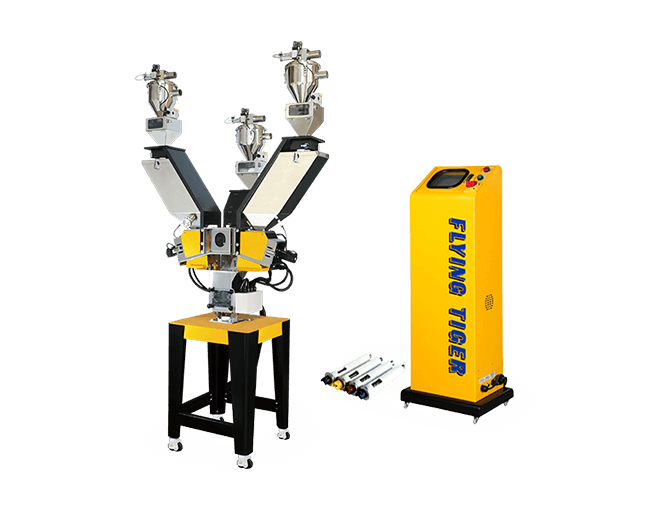

Loss-In-Weight Master Batch Doser

Simultaneous coloring automatically for saving working hours and storage space.

FEATURE

- Simultaneous coloring automatically for saving working hours and storage space.

- Master-batch diversion designed is to ensure more consistent & accurate mixing and quick material changing.

- It can mix perfectly with master-batch and material accurately without mixer.

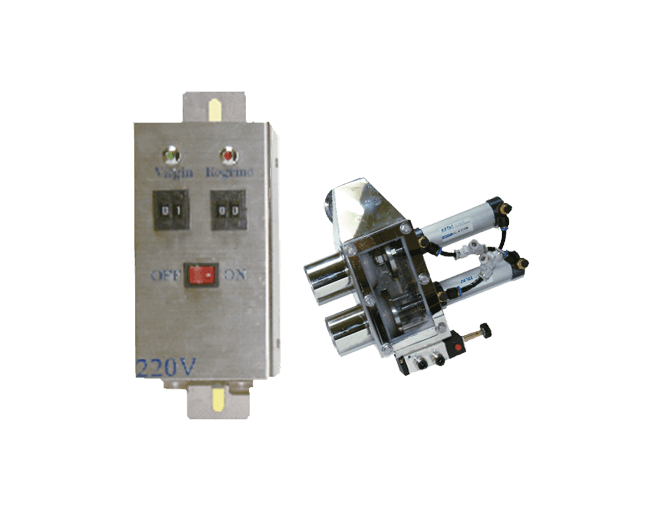

- Servo motor has perfect control of RPM speed, and with PLC and advanced loss -in-weight system the doser can automatically calculate the most accurate RPM. Therefore, Flying Tiger doser can work as the most efficient, accurate and stable.

- PLC& human-machine interface is easy to use, and is able to save up to 20 sets of data.

- There is a low material level alarm in buffer tank, which makes no worry of material shortage.

- To avoid injection machine sometimes has an unstable screw back, the dosing timer is design in IMD-L series to solve unstable master-batch adding cause by unstable screw back of the injection machine.

- To ensure the color consistency, EMD-L series will operate simultaneously when the RPM of extruder screw is adjusted.

SPECIFICATIONS

|

Model |

Injection |

KIMD-06L |

KIMD-08L |

KIMD-15L |

KIMD-30L |

KIMD-45L |

KIMD-60L |

||

|---|---|---|---|---|---|---|---|---|---|

|

Extrusion |

KEMD-06L |

KEMD-08L |

KEMD-15L |

KEMD-30L |

KEMD-45L |

KEMD-60L |

|||

|

Dosing Screw |

Diameter |

MM |

ø6 |

ø8 |

ø15 |

ø30 |

ø45 |

ø60 |

|

|

Color |

White |

Green |

Red |

Blue |

Black |

Gray |

|||

|

Dosing Motor |

Type |

Servo Motor, 220V, 1Phase |

|||||||

|

Power |

W |

400 |

|||||||

|

Speed |

RPM |

1~1000 |

|||||||

|

Control Type |

5.7" Color Touch Panel, with Loss-In-Weigh and PLC control |

||||||||

|

Dosing Weight |

GRAM/TURN |

0.05 |

0.5 |

2.1 |

4.1 |

28.9 |

145.8 |

||

|

Dosing Capacity |

KG/HR |

0.01 ~ 3.0 |

0.03 ~ 30.0 |

0.13 ~ 126.0 |

0.30 ~ 246.0 |

1.74 ~ 1,734.0 |

8.75 ~ 8,748.0 |

||

|

Buffer Hopper |

LITER |

6 |

30 |

||||||

| Power Utility | Single Phase | ||||||||

|

Max power |

KW |

0.3 |

|||||||

|

Dimension |

Doser |

CM |

85.5*25.5*74 |

117*30*106.5 |

|||||

|

Controller |

CM |

46*34*113 |

|||||||

|

Approx. Weight |

Doser |

KG |

31 |

58 |

|||||

|

Controller |

KG |

40 |

|||||||

|

Options |

1.Material Receiver 2.Auto-Loader 3. Loss-In-Weight hopper frame |

||||||||

|

Remarks |

1.Dosing capacity will be varied by material type. |

||||||||