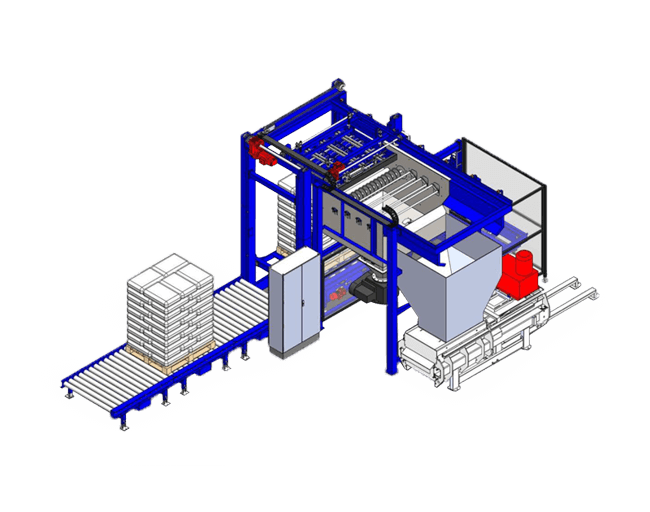

FEATURE

- Increase in capacity

- Less man-hours

- Improved ergonomics (reduction of back injuries)

- Safer working environment

HOW IT WORKS

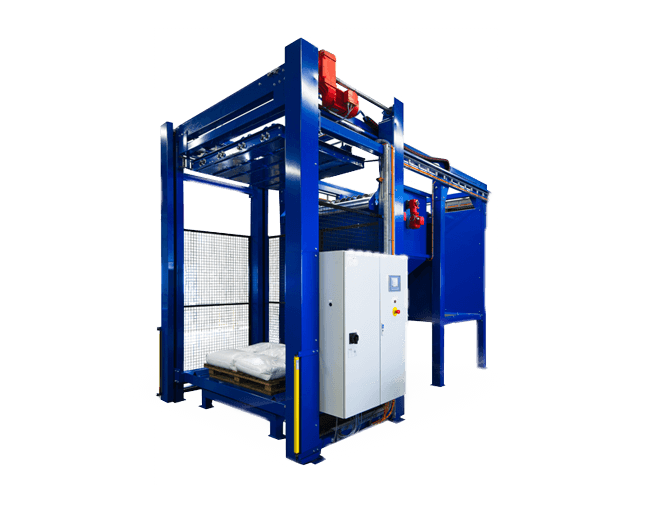

STEP 1

Automatic bag Depalletiser Full pallets (with stacked bags) are placed in the lift.

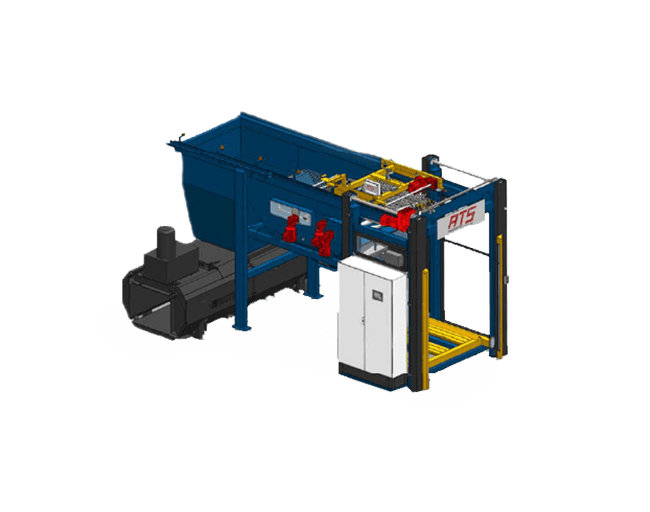

STEP 2

- The full pallet in the lift is then lifted up to the shuttle with gripping hooks.

- The integrated grippers grab the top layer of bags.

- Then the lift moves down. The top layer of bags is now hanging onto the shuttle.

STEP 3

- The shuttle then moves horizontally over the rotating blades.

- The blades cut the bags open, and the product falls into the product buffer.

- An agitating system ensures that the bags are emptied.

STEP 4

Once the bags have been emptied, the shuttle moves to the farthest position and drops the empty bags in the empty bag compactor.

STEP 5

- After releasing the empty bags, the shuttle returns to its starting point to grab the next layer.

- When the pallet is completely empty, the empty pallet can then be taken away using a fork-lift truck (or be stacked with an optional pallet stacker).